Industrial Processing Odours: Managing Emissions Before They Escape

Odour control in industrial processing and manufacturing environments has evolved from reactive masking to proactive emissions management. Whether in chemical processing, food manufacturing, metal finishing, or pharmaceutical production, controlling industrial odours and volatile organic compounds (VOCs) before they reach the atmosphere is now an engineering necessity—not a courtesy.

In this article, we explore how modern facilities are managing odour and VOC emissions before they escape—by treating them inside ducts, stacks, and process exhaust systems using advanced misting and neutralization technologies such as XStreme and AirSolution.

You’ll learn:

- What drives industrial odour formation

- Why pre-release treatment is crucial

- The engineering behind misting and stack injection

- How XStreme and AirSolution deliver measurable results

- Best practices for compliance and sustainability

1. Understanding Industrial Odour and Emission Sources

1.1 What Are Industrial Odours?

Industrial odours are airborne chemical compounds emitted during production, drying, heating, or reaction processes. Unlike typical “nuisance odours,” these compounds often include volatile organic compounds (VOCs), ammonia, aldehydes, amines, and sulfur-based gases—many of which are regulated due to their health or environmental impacts.

Common Odour-Generating Industries:

- Chemical and petrochemical processing

- Paints, coatings, and solvent-based manufacturing

- Food rendering and flavoring facilities

- Pharmaceutical and cosmetic production

- Metal plating and finishing plants

- Pulp and paper mills

These facilities emit complex mixtures of organic vapours that interact in the atmosphere, creating odour plumes detectable kilometers away.

👉 Learn more about VOC definitions and sources from the U.S. Environmental Protection Agency (EPA):

https://www.epa.gov/indoor-air-quality-iaq/what-are-volatile-organic-compounds-vocs

1.2 Why Industrial Odours Are Hard to Manage

Industrial odours are not single compounds but chemical cocktails. Factors such as heat, pressure, moisture, and exhaust velocity affect how odourants behave in stacks and ducts.

Key challenges include:

- High airflow rates: large volumes dilute odour concentrations but increase dispersion range.

- Complex chemistry: hundreds of reactive VOCs require broad-spectrum neutralization.

- Process variability: emissions fluctuate with batch cycles or product changes.

- Thermal effects: hot airflows can carry VOCs long distances.

As a result, traditional surface spraying or room deodorization is ineffective. The solution lies inside the process stream—where emissions can be treated directly at the point of release.

2. The Case for Pre-Release Odour Treatment

2.1 Why “End-of-Pipe” Isn’t Enough

Most odour strategies focus on the ambient environment—scrubbers, biofilters, or carbon beds installed at the exhaust outlet. While effective, they’re often costly, maintenance-intensive, and limited by contact time.

Treating emissions before they escape—through stack and duct injection systems—offers major advantages:

- Real-time neutralization of VOCs and odourants in motion

- Reduced chemical load on downstream scrubbers or filters

- Lower ambient odour footprint

- Improved community compliance

- Reduced corrosion and deposition in ducts

According to the European IPPC Bureau, integrated emission management is central to the Best Available Techniques (BAT) approach for odour control in industry:

https://eippcb.jrc.ec.europa.eu/reference/waste-treatment

2.2 Stack and Duct Injection Explained

In stack and duct injection, atomized neutralizing agents are introduced directly into the airflow path within exhaust ducts or stacks. The fine mist interacts with odour molecules and VOCs in transit, neutralizing them through:

- Oxidation (conversion to non-volatile species)

- Molecular bonding (odorant binding)

- Reaction with sulfur and nitrogen compounds

To be effective, the mist must have:

- Small droplet size (≤10 microns) for maximum contact

- Uniform distribution across the air stream

- Controlled injection pressure to match duct velocity

- Chemical compatibility with exhaust constituents

This is where XStreme and AirSolution technologies excel.

3. XStreme + AirSolution: The Advanced Approach to Industrial Odour Control

3.1 XStreme – Precision Misting for Industrial Environments

XStreme is a high-pressure misting platform engineered for challenging industrial applications. It produces ultra-fine droplets that stay airborne long enough to interact with odour molecules in fast-moving exhaust streams.

Core Capabilities:

- Delivers droplets 5–15 µm in diameter

- Withstands heat, humidity, and corrosive atmospheres

- Operates in ducts, stacks, and large processing areas

- Integrates with PLC or SCADA systems for automated control

- Configurable for multiple injection points across a facility

By controlling droplet density and dispersion, XStreme ensures uniform chemical distribution—even in high-velocity airflow zones where contact time is measured in seconds.

3.2 AirSolution – Odour Neutralization Chemistry

While XStreme provides the hardware, AirSolution provides the chemistry. Its formulations are non-toxic, biodegradable, and reactive, designed to neutralize a broad spectrum of industrial odours and VOCs.

Mechanism of Action:

- Oxidation: Converts reduced sulfur compounds (like H₂S and mercaptans) into inert sulfates.

- Binding: Reacts with aldehydes and organic acids, preventing re-volatilization.

- Encapsulation: Encloses odour molecules, reducing volatility.

Unlike masking agents that merely overlay fragrance, AirSolution chemically interacts with odorous molecules for true neutralization.

👉 Reference: Learn about chemical oxidation and VOC treatment mechanisms at Britannica:

https://www.britannica.com/technology/air-pollution-control

3.3 The Synergy: XStreme + AirSolution

Together, these systems deliver a turnkey duct and stack treatment solution that intercepts odours before they exit the building.

Component | Function | Benefit |

XStreme | Atomizes AirSolution into exhaust air stream | Uniform droplet dispersion |

AirSolution | Reacts with VOCs and odour molecules | True chemical neutralization |

Stack Injection System | Treats emissions before ambient release | Prevents off-site odour |

Automation Controls | Adjusts flow based on process activity | Chemical efficiency |

This combination achieves rapid, scalable odour reduction without complex infrastructure modifications.

4. Key Industrial Applications

4.1 Chemical Processing Facilities

Challenge: Complex VOC mixtures from solvents, polymers, resins, and catalysts.

Solution: XStreme injects atomized AirSolution mist into exhaust stacks post-reactor or after condenser units. The fine droplets react with VOCs and sulfur species, reducing odour and corrosion risk.

Result: Up to 90% odour reduction reported in pilot installations.

4.2 Food & Flavour Manufacturing

Challenge: Odours from cooking oils, protein degradation, and flavour compounds.

Solution: Inline duct injection neutralizes odours without affecting product quality.

Benefit: Reduced complaints and improved compliance with local air quality regulations.

For more on food odour management, see the World Bank’s guidance:

https://openknowledge.worldbank.org/handle/10986/37159

4.3 Paints, Coatings, and Printing

Challenge: High VOC emissions from solvent evaporation.

Solution: Stack injection reduces odorous organics before they mix with outside air, reducing ozone precursor formation.

Reference: VOCs are significant precursors of ground-level ozone and smog (EPA).

4.4 Waste Gas Treatment & Incineration

Challenge: Post-combustion odours from incomplete oxidation or acid gases.

Solution: Duct injection after quench or scrubber stages enhances gas-phase neutralization.

5. Engineering Design: How Stack and Duct Injection Works

5.1 System Layout

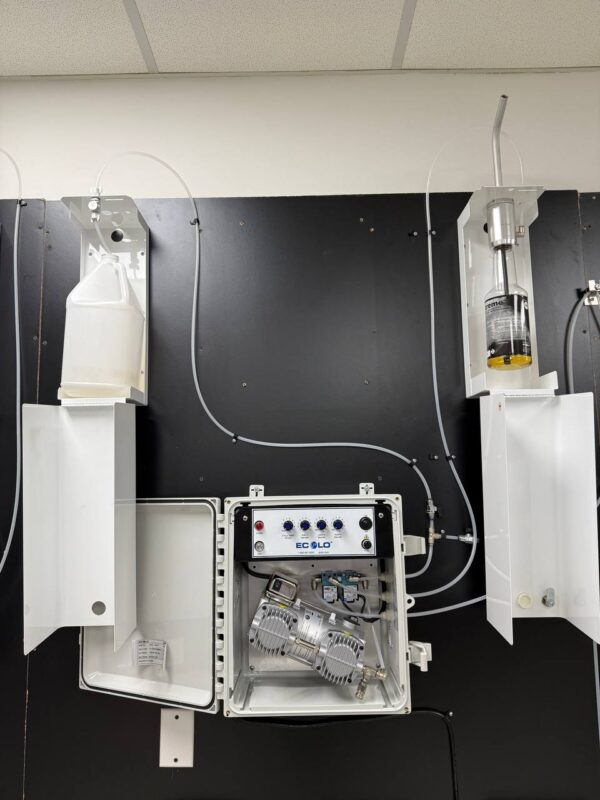

- Injection Ring: Stainless steel manifold with evenly spaced nozzles.

- XStreme Pump Module: Pressurizes AirSolution for fine mist generation.

- Mixing Section: Duct segment ensuring sufficient contact length (typically 10–15 m).

- Control Panel: Regulates flow based on duct velocity, temperature, or VOC readings.

5.2 Droplet Physics

Effective neutralization depends on droplet residence time. Droplets must:

- Match or slightly lag the air velocity.

- Have sufficient density to maintain turbulence contact.

- Evaporate slowly enough for chemical reaction to occur.

Studies show sub-10 µm droplets achieve the highest collision probability with airborne VOC molecules. (NCBI)

5.3 Integration with Existing Systems

The XStreme + AirSolution system complements:

- Wet Scrubbers: Reduces chemical consumption by pre-neutralizing odours.

- Carbon Filters: Extends media life by reducing load.

- Biofilters: Stabilizes inlet concentrations for better biological performance.

This flexibility makes it suitable for both new facilities and retrofits.

6. Case Study: Mid-Size Resin Manufacturing Plant

Background:

A North American resin producer experienced odour complaints due to VOC and H₂S emissions from process stacks. Conventional scrubbers couldn’t handle variable loads.

Implementation:

- Installed XStreme high-pressure injection ring at stack base.

- Used AirSolution 9100 formulation tailored for sulfur-organic compounds.

- Integrated PLC feedback from VOC sensors.

Results after 60 days:

- 82% reduction in total VOC odour units.

- 70% drop in community complaints.

- 30% lower scrubber chemical consumption.

Improved worker air quality at vent outlets.

7. Compliance, Sustainability, and Worker Safety

7.1 Air Quality Regulations

Most jurisdictions impose strict limits on VOCs and odour emissions under national clean-air frameworks:

- EPA Title V permits (U.S.)

- European Industrial Emissions Directive (IED)

- Canadian Ambient Air Quality Standards (CAAQS)

Proactive duct and stack treatment helps facilities stay within Total Odour Units (TOU) and H₂S limits, while improving community relations.

7.2 Worker Health

By reducing emissions inside the facility, operators benefit from lower exposure to:

- VOCs (linked to eye and respiratory irritation)

- H₂S (acute toxicity at high levels)

- Aerosolized organic acids

👉 For occupational exposure guidelines, see OSHA’s H₂S standards:

https://www.osha.gov/hydrogen-sulfide/hazards

7.3 Sustainability

AirSolution products are biodegradable and water-based, avoiding the secondary pollution concerns associated with harsh oxidizers or solvents. Coupled with XStreme’s efficient dosing, the system supports:

- Lower chemical footprint

- Reduced water and energy consumption

- Carbon neutrality targets via emission minimization

8. Measuring Success: KPIs for Industrial Odour Control

KPI | Measurement Method | Typical Goal |

H₂S (ppm) | Continuous gas sensors | <1 ppm at stack exit |

Odour Units (OU/m³) | Dynamic olfactometry | >80% reduction |

VOC Concentration (mg/m³) | GC/MS sampling | <50% baseline |

Complaint Frequency | Community log | >70% reduction |

Scrubber Chemical Use | Flow metering | –25–40% |

Regular monitoring ensures performance verification and regulatory defensibility.

9. Future Outlook: Smart Odour Control Systems

Emerging innovations are transforming emission control from static to adaptive:

- AI-based feedback adjusting misting intensity by VOC readings.

- IoT sensors transmitting real-time H₂S and odour data to dashboards.

- Hybrid air-treatment models combining neutralization with photocatalysis.

- Predictive odour mapping using CFD (Computational Fluid Dynamics) and weather data.

These trends align with Industry 4.0 principles—integrating environmental performance directly into production analytics.

10. Implementation Best Practices

- Characterize Emissions: Identify odourant species via lab or field testing.

- Design for Contact Time: Ensure 10–15 m mixing length for mist-air interaction.

- Use Multiple Injection Points: For complex ducts or multi-branch stacks.

- Calibrate Flow Rates: Match injection volume to CFM and duct cross-section.

- Maintain Systems: Clean nozzles monthly; inspect pumps and lines quarterly.

- Train Operators: On chemical safety, dosing rates, and troubleshooting.

Following these steps maximizes ROI and system longevity.

11. Comparative Technology Overview

Technology | Phase | Strengths | Limitations |

Activated Carbon | Gas-phase adsorption | High efficiency for VOCs | Requires frequent media change |

Biofiltration | Gas-phase biological oxidation | Sustainable, low energy | Sensitive to temperature and moisture |

Wet Scrubbing | Chemical oxidation | Effective for acids and ammonia | High water & reagent use |

Thermal Oxidation | Combustion of VOCs | Complete destruction | High energy cost |

XStreme + AirSolution | Duct/Stack injection | Fast, adaptable, low OPEX | Requires tailored design |

This flexibility positions XStreme + AirSolution as a complementary or standalone system across multiple industries.

12. Conclusion: Controlling Odours Before They Leave the Stack

Industrial odour control is no longer about neutralizing smells after they spread—it’s about engineering emissions at the source. By combining XStreme’s precision misting technology with AirSolution’s advanced neutralization chemistry, operators can intercept odour and VOCs before they escape into the atmosphere.

The Result:

- Significant reduction in H₂S and VOC emissions

- Improved compliance and community relations

- Lower chemical and energy consumption

- Enhanced worker safety and air quality

Industrial leaders across chemical processing, manufacturing, and waste treatment are already proving it works.

Proactive. Sustainable. Scalable.

That’s the future of odour management—powered by XStreme + AirSolution.